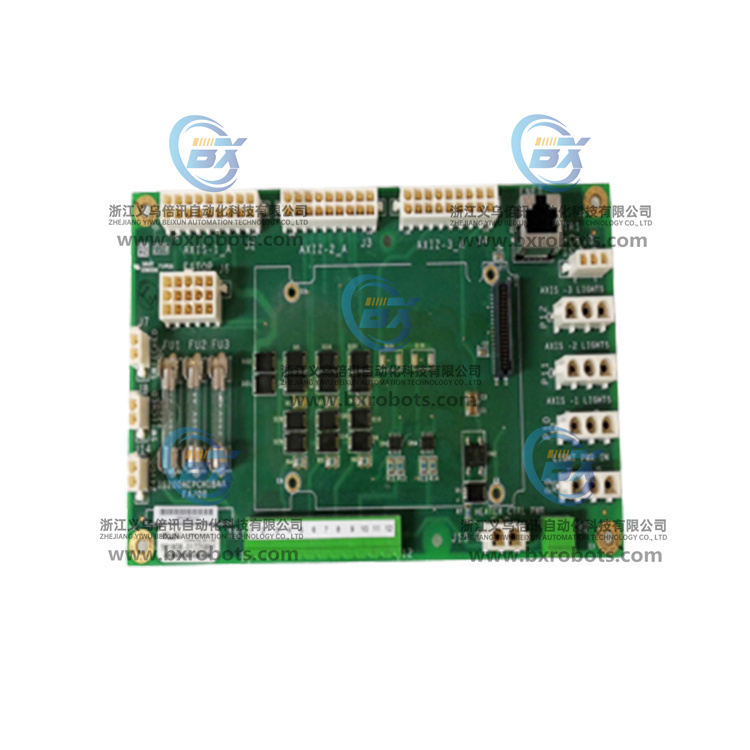

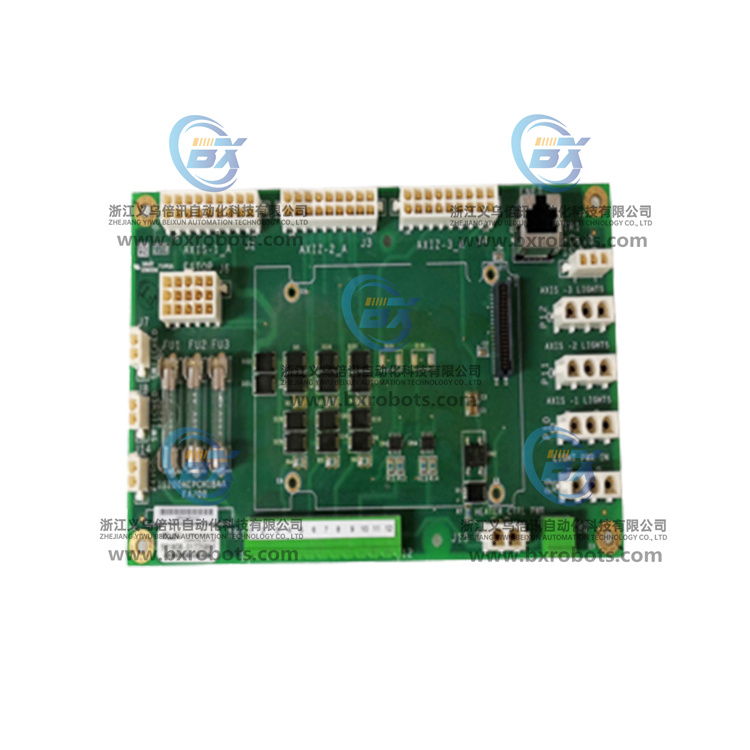

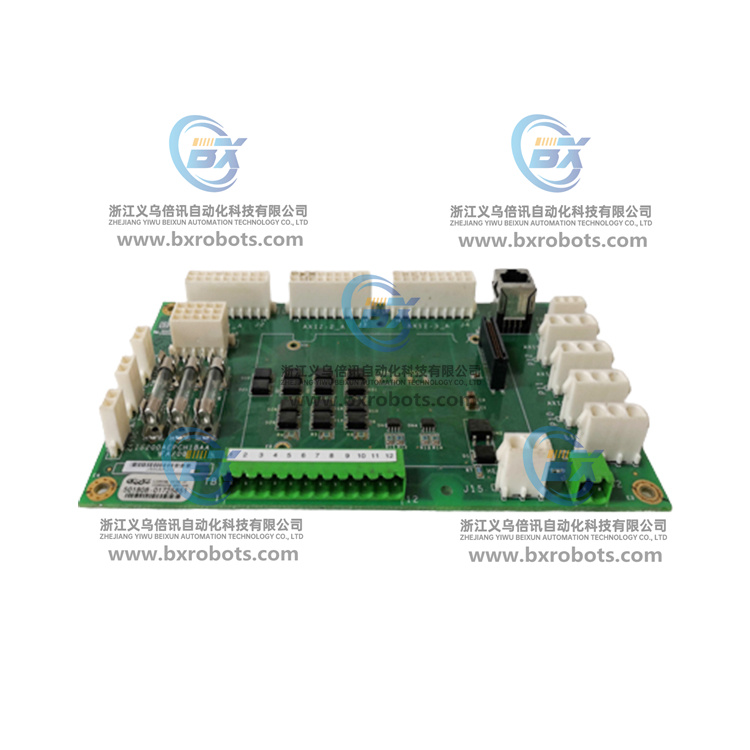

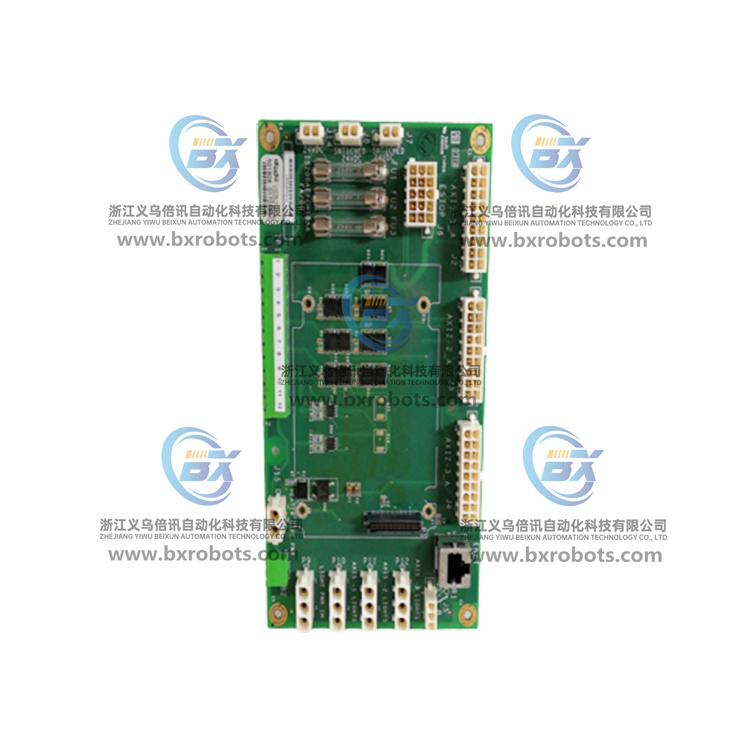

GE IS200ACLEH Mark VI系统燃机卡

GE IS200ACLEH 汽轮机又称蒸汽透平发动机,是一种旋转式蒸汽动力装置。高温高压蒸汽通过固定喷嘴,变成加速气流,喷射到叶片上,使带叶片排的转子旋转,对外做功。汽轮机是现代火力发电厂的主要设备,也用于冶金工业、化学工业和船舶电站。汽轮机的结构部件由转动部件和固定部件组成。

GE IS200ACLEH Turbine, also known as steam turbine engine, is a rotating steam power unit. High-temperature and high-pressure steam passes through a fixed nozzle and becomes an accelerated airflow, which is injected onto the blades, causing the rotor with blade rows to rotate and do work externally. Turbine is the main equipment of modern thermal power plant, also used in metallurgical industry, chemical industry and ship power station. The structural parts of the turbine consist of rotating parts and fixed parts.

涡轮机机电主轴弯曲的原因

1. 汽缸隔热不良。如果汽缸的隔热性能较差,在汽轮机启动和停机时,上下汽缸的温差会很大。在汽轮机启动和停机过程中,上缸和下缸会产生较大的温差。一般情况下,上缸的温度高于下缸的温度,这使得上缸在启动和停机过程中会产生较大的温差。一般情况下,上缸温度高于下缸温度,使得上缸膨胀高于下缸,上缸拱起。

Causes of bending of turbine electromechanical spindles

1. Poor cylinder insulation. If the cylinders are poorly insulated, the temperature difference between the upper and lower cylinders will be large during turbine startup and shutdown. During startup and shutdown of the turbine, a large temperature difference is generated between the upper and lower cylinders. Generally, the temperature of the upper cylinder is higher than that of the lower cylinder, which causes a large temperature difference between the upper cylinder during startup and shutdown. Generally, the temperature of the upper cylinder is higher than that of the lower cylinder, which makes the upper cylinder expand higher than the lower cylinder and the upper cylinder arch.

2. 水或冷蒸汽进入气缸。

3. 转子热弯曲造成永久弯曲。

4. 由于运行时的强烈振动,会产生动静摩擦和摩擦后产生的热量。由于剧烈的振动摩擦、

摩擦部分的温度非常高,导致材料的屈服强度降低。过高的热应力会导致

轴的热变形,并造成轴向摩擦侧的凸起弯曲,这进一步加剧了温升,导致轴的弯曲增加。轴弯曲加剧。

2. Water or cold vapour enters the cylinder.

3. Permanent bending caused by thermal bending of the rotor.

4. Due to strong vibration during operation, dynamic and static friction and heat generated after friction are generated. Due to intense vibration friction,

The temperature of the friction part is very high, resulting in a reduction of the yield strength of the material. Excessive thermal stress leads to

thermal deformation of the shaft and causes raised bending of the axial friction side, which further increases the temperature rise and leads to increased shaft bending. Increased shaft bending.